| This page is in the process of a rewrite! This page is in the process of being rewriten. Some information on this page may differ from how it actually works on Delta-V. A lot of information will be incomplete or may contain placeholders. You can help Delta-V by expanding it To-Do: Big rewrite needed - TEG burn chambers, Triton production, Frezon production |

| This page is a stub! This page is a stub, meaning it is considered too short, incomplete and/or lacking information about the page's subject. You can help Delta-V by expanding it. |

Atmospheric Technicians are concerned with maintaining a safe atmosphere in the station by:

- Setting up the station's gas distribution system, or "distro," to supply the station with breathable air.

- Using handheld gas analyzers and fixed air alarm systems to monitor levels of both safe and hazardous gases.

- Utilizing holofan projectors and inflatable walls to cordon off hull breaches or gas leaks.

- Moving and placing portable scrubbers to manually filter the air in case of escaped gases.

Understanding the Distribution Area

The distribution area (or, Distro) refers to the area of Atmos that contains the origin point of the air and waste networks, as well as the chambers for storing and processing the gases.

A distro’s purpose is to:

- Supply oxygen and nitrogen to a gas mixer which supplies air to the station.

- Filter waste and toxic gases from the station.

- Store gases in a secure area where Atmos Techs are able to work with them.

The distro is able to do all of these things because of the system of pipes, pumps, filters, and mixers it is outfitted with. Every distro does NOT require placing/altering pipes for it to function properly!

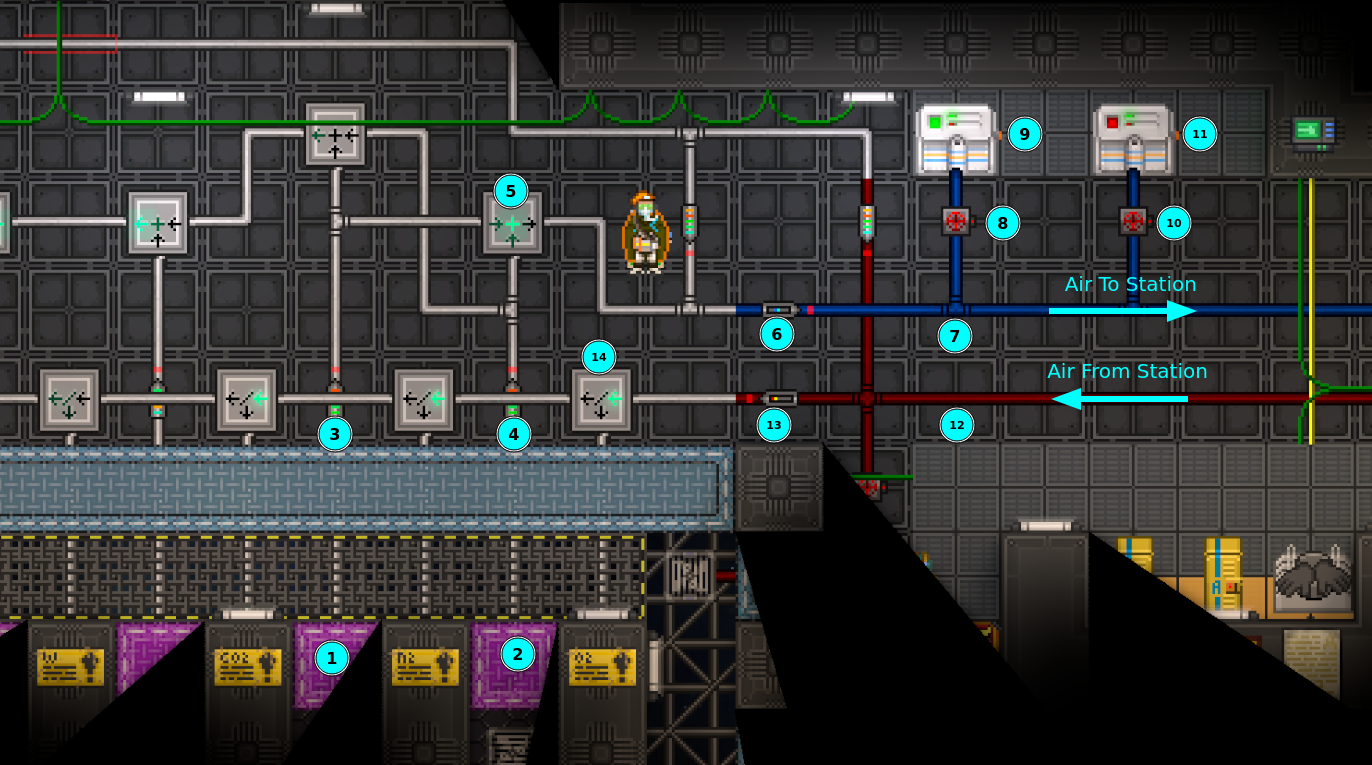

Distro Annotated

A typical distro layout is shown below:

- Nitrogen holding chamber with (maybe) a nitrogen gas miner

- Oxygen holding chamber with (maybe) a oxygen gas miner

- Pump for moving nitrogen to the mixer

- Pump for moving oxygen to the mixer

- Mixer to mix nitrogen and oxygen in an appropriate ratio for the station

- Volume pump to move mixer output to the station's main distro pipe

- Main distro pipe

- Valve to shut off freezer

- Freezer to reduce air temperature in distro

- Valve to shut off heater

- Heater to increase air temperature in distro

- Main waste pipe

- Volume pump to move air into the filter banks

- Bank of filters to separate different types of gases from the waste pipe

Holding Chambers

Holding chambers store a supply of gas for you to pump into the station when needed. Some stations come with gas miners that produce an unlimited supply of the mined gas. Walls and windows prevent gas from escaping to space; if the holding chambers are broken, then the gas inside will be lost.

Holding chambers may be labeled with the type of gas that they are designed to store.

Use pumps to move gases in and out of holding chambers.

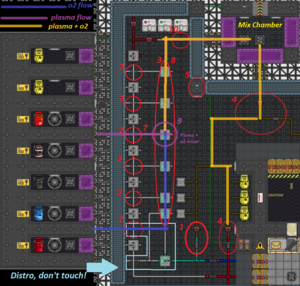

Mix Chamber

The mix chamber is an empty holding area with its own separate loop of pipes and pumps in atmospherics. The mix loop is generally marked with brown pipes and the holding chamber can usually be found close to the external hull, separated from the station by reinforced walls and windows. There will be an emergency button nearby to vent the chamber to space if you need to dump your mix in case an accident arises, or you just wish to reset the chamber for a new mix. The mix chamber is here for you to experiment with different mixes, ratios, temperatures, and pressures while combining gases.

On most stations the Mix chamber will loop around to either to the distro loop, or back to the waste loop. It is generally a good practice to have your mix loop flow back into the waste loop to recycle any unspent gases. You should NEVER have the mix loop flow into distro unless you have a very good reason. Most savvy Atmospherics Technicians physically disconnect the mix loop from distro at round start to prevent an easy sabotage target or accident from occurring later in the round.

See the guide to Gases if you are interested to learn how different gases interact with each other at different temperatures and pressures.

See the guide to Setting up the mix chamber if you want to learn how to properly and safely use the mix chamber.

Setting Up The Distro

Main Distro Loop

The first step in setting up the distro is to determine which line goes to the air vents. It is usually colored blue to make it easily identifiable. Once you’ve identified that line, follow the pipes back to the Oxygen and Nitrogen chambers.

Out of the chambers, there are two lines of pipes, one that goes into the chamber from a gas filter (14) and one that comes out of the chamber through a pump (3), (4). Turn these pumps on and set them to max pressure. After that, follow the pipe that leads out of the chambers and you’ll find they eventually lead to a gas mixer (5). Set it to the correct air mix (21% Oxygen to 79% Nitrogen) and pressure. If there is a pump after the mixer, you can set the pressure to 4500kPa. Otherwise, set the pressure to 200kPa

Air vents will pump air from distro into the station as long as the pressure inside distro is positive. Increasing the pressure inside distro allows the air vent pumps to move air faster. Contrary to popular belief, the pressure inside does not set the pressure of air coming out of the actively pumped air vents that start connected to distro.

Check the pressure of distro at round start and periodically throughout the shift. Low or slowly rising distro pressure at round start is a sign of shoddy station quality design flaws causing low flow rates into distro. Low distro pressure in the middle of the round may be indicative of spacing on the station.

Waste Loop

Waste, or the waste loop, is usually marked with red pipes and is responsible for removing waste gas around the station via scrubbers. These pipes start and end in atmospherics and are looped around the entire station. The main purpose of the waste loop is the ensure that harmful gases get removed from the station's atmosphere. Scrubbers will remove gas from the hallways and return it to Atmospherics where it will then be separated by gas filters into various holding chambers. Harmful gases will be deposited into their assigned chambers and the breathable air will once again make its way back to Distro and into the station to continue the cycle.

To set it up, follow the line and configure all of the gas filters going into the chambers to the correct gas (14). At the end of the waste line you will find a passive vent going to space. All the unfiltered gas will end up in space. Make sure the valve leading to the vent is opened.

Gas Recycling

Not all stations come with an O2 miner, Shōkō in particular has no O2 gas miner, so they require a gas recycler to get Oxygen. It turns Carbon Dioxide into Oxygen and Nitrogen Oxide into Nitrogen. It takes a bit of instruction to use, and the basic premise is as follows:

- A mix of gases that is at least 300 degrees Celsius and pressurized no less than 3000 kPa enters through the north side of the recycler, and the mix exits out the south side, with some of the carbon dioxide converted to oxygen and some of the nitrous oxide converted to nitrogen.

The recycler loop must be heated to at least 300 degrees Celsius (~575 Kelvin), after that, pressure must be at least 3000 kPa. Pressure can be added by increasing the presence of other gases (not necessarily CO2 or N2O) into the recycler loop’s pipes. Nitrogen is usually abundant and inert, so it is a good contender. Pressure in the pipes will lower as gases leave the recycler loop, so a pump is often placed at the end to regulate pressure.

Note that gases that leave the recycler will remain heated, so it’s important to regulate temperature if the O2 is going to be used in station air. A freezer can be placed after the recycler loop, or after the breathable air mixer to ensure the station doesn’t burn alive.

Optimizing The Distro

You can optimize the distro the layout to more effectively pump gases into the station. Specific steps to do so vary from station to station. Here is an example of setting up distro for the example above:

- Remove (6) and replace it with a straight pipe segment. Pumps reduce gas flow rate, and when spacing occurs, (6) is typically a bottleneck when re-pressurizing the station.

- Set (5) to output 200 kPa. The pressure in the distro pipe influences how quickly air vents can move air from distro into the station. Setting this too low reduces the flow rate, but setting this too high could be dangerous if a Traitor replaces an air vent with a passive vent.

- Increase output pressure of (3), (4), (13) and (14) to their maximum settings.

Species Specifics

Not all species breathe oxygen! In fact, there are some that can breathe other gasses, and some which must breathe other gasses:

- Oxygen is toxic to Voxes. They breathe nitrogen instead. Many stations have a dedicated "Vox Box" room which only has nitrogen.

- Water vapour is harmful to slimes.

- Feroxi can breathe water vapour.

- Diona can breathe CO2 in addition to oxygen.

Keep this in mind when setting up the distro. Adding water vapour would harm slimes!

Setting up and understanding the Thermoelectric Generator (TEG)

| This page is a stub! This page is a stub, meaning it is considered too short, incomplete and/or lacking information about the page's subject. You can help Delta-V by expanding it. |

This section is currently an incomplete placeholder guide. I do not know this stuff sufficiently to write the guide. For better info, check #atmos thread on Discord.

The TEG has two pipe inputs for gasses - an input for a hot gas, and an input for a cold gas.

The TEG works by transferring heat energy from the hot input gas to the cold input gas, generating power as part of the transfer. Currently (June 2025) the amount of heat transfered from a gas when it passes through the TEG is 10% - meaning 90% of heat energy in the gas remains. How much heat energy a gas can "contain" is determined by its specific heat capacity.

Furthermore the efficiency of the TEG scales with the difference in temperature between the hot gas and the cold gas.

Thus, ultimately for the TEG to work we need:

- A cold gas - the "cold loop"

- A hot gas - the "hot loop"

- Continious flow of both gasses.

The cold loop - space radiators and cooling the TEG

You want to use a gas with high heat capacity. Practically this usually also means plasma. Of special note however is frezon - it is a gas that is naturally very cold, making it an excellent coolant. However, acquiring frezon requires a complex set up, and once produced it is far more useful being sold for a lot of cash.

Do you know what's very cold? That's right - spess space. Thus, we use space to cool down our cold loop gasses.

The hot loop - setting up and using the burn chamber

There are two ways to get a hot gas for our TEG - we can either heat it up by exposing it to a very hot area (the burn chamber), or by pumping in the hot gasses from a fire. However, because usual fire product gasses (CO2) usually have very poor specific heat capacity, and can be difficult to supply consistantly, almost always the former set up is used. Furthermore, discarding the gas after using it to power the TEG is very very wasteful - recall that only 10% of the gas'es heat is used every time a gas passes the TEG!

Therefore instead we set up a system, where a gas is passed through a very hot room through radiators, taking up heat from it, passes through the TEG, and then is pumped back around to be heated up again. This is known as the "hot loop". And the aformentioned hot chamber can be made by, well, starting a fire in it - this is called "the burn chamber".

The Burn Chamber

Usually a mix of 5% plasma and 95% oxygen is used. Plasma and oxygen burn at a ratio of 1:1, however, plasma is a lot more precious than oxygen. The excess of oxygen instead becomes the "holding gas" - a gas that remains in the burn chamber to keep it hot.

The burn mix, as it is known, can be made either by mixing gasses from two canisters, or by mixing gas from a plasma can and gas from the oxygen miner. At round start, most TEG loops are unfortunately set up with the far more annoying former.

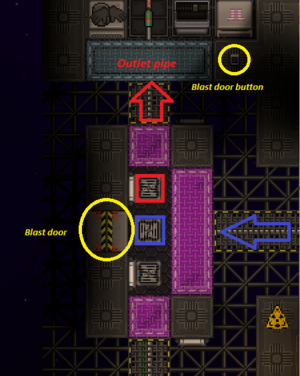

Keep in mind that eventually the burn chamber will run out of room to inject more plasma to burn. Thus it needs to be regularly vented - burn chambers are set up with blast doors than open into space for precisely this purpose.

Igniting the burn chamber can be done in several ways. Ideally you use an igniter, placed in the burn chamber and linked to a button. However, not all TEG burn chambers come with one, and furthermore the igniter is actually a pretty poor ignition tool.

The Hot Loop

The second, crucial part of our set up is the hot gas we will pump through the TEG. This can be in a way understood as a way to transfer heat from out burn chamber to the TEG. Thus, similarly to the cold gas, you want to use a gas with high heat capacity. Practically this usually also means plasma.

We want our hot loop gas to become as hot as possible. This is for a couple reasons, mentioned before - only 10% of a gas'es heat is used each time it passes through, and the efficiency of the TEG scales based on the temperature difference between the cold loop and the hot loop.

In a typical hot loop set up there will be 3 critical pumps and 1 critical valve.

- The burn chamber input pump.

- The burn chamber output/TEG input.

- The TEG output.

- The pressure release valve.

Recall, that it is vital there is a continious flow of gas through the TEG. If the flow stops, the TEG immidiatelly ceases producing power.

You may recall a crucial formula from Atmospheric Science: pV = nRT. Practically this means the hotter same volume of gas becomes, the higher the pressure. Because all pumps (including volumetric ones!) have pressure limits, at which they will stop pumping, this means should your pressure get too high, your TEG will "stall".

The pressure release valve is your "emergency button" to reduce pressure should a stall occur. However it is better to avoid a stall in the first place.

A few things can help you in achieving that:

- Use as little gas as possible for your hot loop

- Use volumetric pumps as they have a higher pressure limit. Keep in mind that mixers act as pressure pumps, while filters act as volumetric pumps!

* Other (add here)

A simple step-by-step guide to set up and maintain a station's TEG

Ok that's a lot of text right? A lot to take in? Yeah. So here is a simple step-by-step to practically set up your TEG at round start, so the station has power.

The Mix Chamber

About this guide

So you are ready to graduate from Station Engineer to Atmospherics Technician and are looking for something a little more in-depth than laying down wires and clicking on boxes to set up the AME? Well look no further, after reading this you will be smarter than those dummies next door and have the skills to show for it!

This guide is designed to walk you through, step by step, in creating your first burn mix using the mix chamber. After completion you should have a better understanding on how the mix chamber functions. If everything is done right you will make your engineer coworkers jealous and will be one step closer to mastering atmospherics! If things go wrong, angry crewmembers will be yelling death threats and the admins will very interested in you! Just remember to always learn from any mistakes and understand where and why something went horribly wrong!

Make sure you have a basic understanding on how atmospherics works.

First things first

So you just started your shift as an Atmospherics Technician on space station 14 and want to use the mix chamber. The very first things you should do is grab your equipment. Make sure you have either your firesuit and helmet or atmospheric hard suit and internals available to provide you some protection in case of an accident. Next, be sure to grab your handy dandy gas analyzer to be able to see what's going on inside those pipes. Lastly and arguably the most important thing you should do at round start is to consult with your fellow atmospheric technicians and Chief Engineer. Declare your intention to use the mix chamber and make sure everyone is on the same page. The last thing you want to have happen is your coworker unwittingly dumping your burn mix into the room by un-wrenching a pipe or finding out that they accidently pumped your burning hot plasma mix into distro.

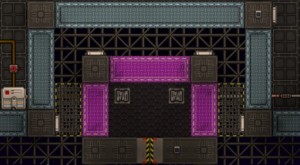

Locating the mix chamber

Look around atmosia and locate the gas mixers by the different gas holding tanks. Follow the gas mixers outlet pipes until they all combine and terminate into a pump or manual valve that leads out of the station's hull. Look through the window and observe if the pumps lead into a nearby empty chamber containing both inlet and outlet passive vents and a blast door. If you found this, congratulations! you have located your mix chamber!

Some stations, usually the small ones, are not equipped with a mix chamber. If the pipes lead to a vent in open space and you do not see a nearby empty chamber then there is mostly likely no mix chamber on this station. Feel free to contact the head of your department and Centcom to complain about station budget cuts!

Setting up the pipes

Every station has a different layout so it is a good practice to always refamiliarize yourself at round start with the mix chamber and the mix loop. After you located the mix chamber follow the pipes that flow into and out of it and get comfortable with where they lead. A general mix loop will take gas from the holding tanks, through gas mixers and into the mix chamber. From there they will exit the chamber and loop into an area where you can connect ports and canisters to extract your gas. Some layouts do not have a canister loop and you might have to create your own if needed. Finally the mix loop will connect into waste where the unused gas will be returned to the gas holding chambers to be recycled and reused at a later time. Once you are 100% sure where the mix loop is you are ready to add gas to the chamber.

- Triple check that the pipes leading out of the mix chamber do not flow into distro. if they do, either physically disconnect them or manually toggle off the pumps.

- Toggle off all the gas pumps, except oxygen and nitrogen, leading out of the gas holding chambers.

- toggle off all the gas mixers with the exception the oxygen and nitrogen mixers used for distro.

- Toggle off all the pumps leading out of the mix chamber up to the waste loop.

- Toggle closed the mix chamber blast doors using the button.

- Use your gas analyzer on the pipes leading into and out of the mix loop and check to see that there is no gas in the pipes. If there is, locate where the gas is coming from and toggle that pump closed. Drain the mix loop by locating the mix to waste pump at the end of the mix loop and toggle it open until the gas is gone. Repeat until all gas is gone.

- Locate the pumps leading out of the oxygen and plasma holding chambers and set them to max pressure.

- Locate where the oxygen flows into the next gas mixer down the line and max the pressure. Be sure to configure the input ratios depending on what side of the mixer the oxygen is flowing into. Do not touch the gas mixers used with oxygen and nitrogen in the distro loop.

- Work your way down the gas mixer line maxing the pressure and configuring the input ratios until you reach the mixer for the plasma holding tank. Set the input for oxygen to be at 66% and the input for plasma to be 33% and set the pressure to be around 100-200kPa.

- Continue down the line up to the chamber opening up and maxing the pressure of all pumps until you see gas flow into the mix chamber.

If everything is done correctly you should see plasma gas in the mix tank. The exact composition of the gas inside should be 66% oxygen and 33% plasma. If you see this then congratulations! you have created your very own burn mix!

(note that you may need to adjust the output pressure of the oxygen and plasma mixer. Too much pressure will clog up the mix chamber and waste pipes with water vapor waste gas as the plasma burns. Too little of a pressure and the plasma fire will burn itself out. Experiment with different pressures to find one you like!)

If you don't see any gas inside the mix chamber chances are that you forgot to toggle open a pump or max the pressure. double check that the blast doors are closed and that all the outlet pumps on the mix chamber are toggled off. Follow the mix loop back from the mix chamber and use your gas analyzer on each pipe segment until you find where the pressure is at. double check that the right pumps are open and that the pressure is maxed. If there is still no gas flowing double check the mixers and check to see the correct inlet ports are set to the right percentage on the mixer interface. If there still isn't gas in the chamber and you double checked every pipe pump and valve then check that there is gas in the holding tanks. Some stations do not have a plasma miner or there might be a breach venting all your gas into space.

Igniting the burn mix

So, your mix chamber is full of sparkling plasma and oxygen, what's next? Firstly, understand that plasma will ignite at higher temperatures. A plasma fire requires both a steady flow of oxygen and plasma to remain ablaze and will create waste gas in the process. There are many ways to ignite your burn mix but the most common and safest way is to wrench a heater on one of the burn mix outlet pipes. A quicker, dumber, more flashier way is to chuck a lit welder or fire source into the chamber before pressurizing it.

Lets go with the heater method. Simply find a heater nearby in atmospherics or steal one from your silly engineer coworkers. Alternatively you can craft one using a machine frame and some components. Once you have acquired your heater, drag that bad boy over to the mix chamber's outlet pipe. Make sure the location you have chosen has pressurized gas from the chamber, use your gas analyzer to check! You may need to add or remove some pipes and a pump to get a suitable location. Once you have the right location, use your wrench to secure it to the pipe. Open the interface, max out the temperature and turn it on. Depending on the amount of burn mix and its temperature you may need to wait a couple of seconds before it combusts into a beautiful plasma fire. Heaters(and freezers) will sometimes act strangely on horizontal and elbow pipes and not heat up the gas inside.. You may need to move it around until you find a place that works for you.

With the addition of holofans, it may be easier to use a holofan to hold back the gas and allow you entry to chuck a lit welder into the burn chamber.

Once your burn mix is lit you may notice it going out sporadically. This is because we still have the mix to waste pipes toggled off and the plasma fire is creating water vapor as a waste gas witch is taking up valuable space, displacing oxygen and plasma and snuffing out our fire. Simply open up your mix loop to waste and watch as the gas gets syphoned out through the loop back into the gas holding chambers. You may need to manually vent the mix chamber using the blast door toggle button to speed up the venting process. Once you have the mix loop connected to the waste loop, plasma and oxygen will continuously flow from the gas holding chambers into the mix chamber, combust into flame, and work its way out through the loop back into the holding chambers ready to start its journey once again.

Congratulations! you now have a fully self sufficient burn mix! The fire will continue to burn until you either run out of oxygen or plasma, or until the waste loop cant keep up with the pressure. Feel free to sit back and relax for a time while watching your burn mix combust into flame.

What now?

Now that we have a stable plasma fire, now what? Well, that's up for you to decide! Experiment with different plasma and oxygen ratios and see how it influences the temperature and pressure. Perhaps try to introduce a third gas into the chamber and see what happens. Extract your burning hot gas into a canister and drag it along behind you to show it off to the crew while grabbing a well deserved snack and drink at the bar. The possibilities are yours to decide! have fun and remember to enjoy the remainder of your shift aboard Space Station 14.